In the evolving world of industrial fluid handling, Air-Operated Double-Diaphragm Pump Manufacturers have established themselves as reliable and efficient contributors to a range of industrial operations. From chemical processing plants to food-grade applications, the use of AODD pumps has increased exponentially due to their versatility, safety, and ability to handle complex materials. As industries continue to prioritize operational efficiency and safety, the role of leading AODD Pump Manufacturers becomes more prominent than ever. In this article, we delve into the technological nuances, market trends, and leading suppliers in the AODD pump manufacturing domain, especially focusing on AODD Pump Manufacturers in India who have emerged as global competitors.

Understanding Air-Operated Double-Diaphragm Pumps

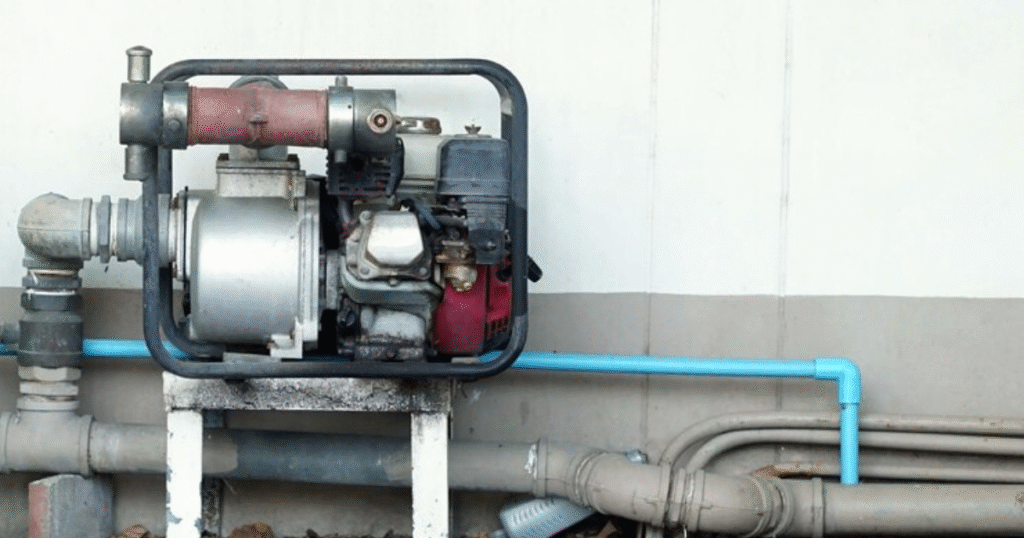

At the heart of industrial pumping systems, Air-Operated Double-Diaphragm Pumps (AODD) work through the reciprocating action of diaphragms powered by compressed air. These pumps are designed without electrical components, making them intrinsically safe for use in hazardous environments. They are well-suited for pumping liquids that are viscous, abrasive, corrosive, shear-sensitive, or contain solids.

The double-diaphragm mechanism ensures consistent flow while avoiding mechanical seals and rotating parts. This greatly reduces the chance of leaks and wear, contributing to long service life and reduced maintenance. The structure generally includes two pumping chambers, check valves, diaphragms, and a central air valve, which together enable the pump to operate with a suction-lift capability and self-priming functionality.

Whether you need to transfer chemicals, resins, paints, adhesives, or food-grade liquids, Air-Operated Double-Diaphragm Pumps have earned a reputation for reliability and adaptability across sectors.

Applications of Standard Duty AODD Pumps in Industry

Standard-duty AODD pumps play a vital role in daily operations across multiple industries. In the chemical industry, they help move acidic and caustic liquids safely without corroding internal components. The food and beverage sector relies on these pumps for gentle handling of viscous and perishable liquids like sauces, syrups, and dairy products. Pharmaceutical manufacturers value the sanitary and clean-in-place (CIP) capabilities of certain AODD models that comply with stringent hygiene regulations.

Water and wastewater management companies use AODD pumps for sludge handling and chemical dosing. Oil and gas facilities prefer them for their non-sparking, explosion-proof nature, especially in upstream and downstream applications. Paints, inks, and coatings benefit from the pump’s ability to manage thick liquids with suspended particles. No matter the industry, AODD Pump Manufacturers design these units to ensure consistent flow, chemical resistance, and high performance with minimal supervision.

Innovation and Engineering by Indian AODD Pump Manufacturers

India has firmly positioned itself among the top nations in engineering excellence, and the AODD Pump Manufacturers in India are no exception. These manufacturers offer global clients high-quality pumps that meet international standards like ISO, CE, and ATEX. Many Indian companies utilize advanced CNC machinery, automated assembly lines, and precision testing setups that ensure each unit performs under extreme operating conditions.

Innovation is at the core of Indian manufacturing. Companies are now developing lightweight composite materials for pump bodies, energy-efficient air valves, and leak-detection systems integrated with Industrial Internet of Things (IIoT) technologies. These improvements are enabling better flow control, faster maintenance cycles, and real-time condition monitoring.

Moreover, many Indian manufacturers have expanded their footprint beyond domestic boundaries. As leading Air Operated Double-Diaphragm Pump Exporters, they serve industries across Europe, the Middle East, Africa, and Southeast Asia, offering custom-engineered solutions with robust documentation, after-sales support, and training services.

The Growing Importance of Pneumatic Diaphragm Pumps

Pneumatic Diaphragm Pump Manufacturers play a crucial role in sectors where electricity cannot be used due to safety regulations or potential explosion hazards. These air-powered pumps deliver smooth flow, handle solids and viscous media, and are available in materials ranging from stainless steel and aluminum to polypropylene and PVDF for chemical resistance.

Because they are self-priming and capable of running dry without damage, pneumatic AODD pumps are particularly favored in mobile, remote, or hazardous setups. In mining operations, they help dewater sites without requiring electrical infrastructure. In chemical tank farms, they handle aggressive liquids with ease. For food manufacturers, pneumatic pumps provide hygiene, cleanability, and low-shear pumping essential for sensitive products.

The precision with which Pneumatic Diaphragm Pump Manufacturers design their systems reflects years of R&D and a deep understanding of industrial challenges. Today, most Indian manufacturers offer a full line of pneumatic pumps along with technical guidance, flow simulation, and installation support to ensure maximum uptime.

Export Excellence: AODD Pump Exporters from India

India’s reputation as a dependable base for AODD Pump Exporters from India is built on consistent product quality, timely delivery, and competitive pricing. Manufacturers here emphasize international compliance by ensuring ATEX certifications, performance testing, and traceability for every part supplied. These efforts have earned the trust of clients across oil refineries in the UAE, chemical processing facilities in Europe, and wastewater plants in Southeast Asia.

Exporters also take care of tailored shipping methods, local warehousing options, and documentation compliance with regulations in target markets. Their global strategies often include participation in international exhibitions, distributor partnerships, and multilingual product catalogs to ensure seamless interaction with clients from various regions.

Heavy-Duty AODD Pumps: Where Strength Meets Reliability

While standard-duty models serve many industries well, there’s increasing demand for Heavy-Duty AODD Pumps Manufacturers who can provide solutions for the most aggressive applications. These include high-viscosity slurries, abrasive suspensions, and liquids at elevated temperatures or pressures.

Heavy-duty AODD pumps are often built with reinforced casings, oversized diaphragms, abrasion-resistant check valves, and high-capacity air motors. These designs are preferred in mining, ceramics, cement, metal processing, and industrial cleaning applications. Many Indian manufacturers offer specialized configurations with multiple inlet/outlet options, jacketed casings for temperature control, and anti-freezing systems for extreme climates.

Their products undergo rigorous lifecycle testing to ensure they maintain optimal efficiency and structural integrity even under demanding 24/7 operations. This robustness, combined with scalable manufacturing and technical expertise, makes Indian heavy-duty AODD pumps a viable alternative to global legacy brands.

Online Transformation: Buy AODD Pumps Online India

With the rise of B2B e-commerce and digital transformation, more users now prefer to Buy AODD Pumps Online India through manufacturer portals, marketplaces, or verified distributors. The advantages of online purchasing include product configurators, downloadable technical datasheets, instant quotation systems, and real-time inventory updates.

Reputed AODD pump companies are also offering virtual assistance via chatbots, remote installation support, live video demos, and detailed comparison charts. These features allow engineers and procurement teams to evaluate pump models, performance curves, chemical compatibility, and certifications without having to visit physical locations.

This digital evolution allows customers to filter options based on diaphragm material, flow rate, pump body, and specific applications—ensuring fast and accurate selection. From small-scale businesses to large EPC contractors, everyone now enjoys the convenience of digital pump procurement with backend support from seasoned Air Operated Double-Diaphragm Pump Suppliers.

Custom Solutions by AODD Pump Manufacturers Near Me

When industries search for AODD Pump Manufacturers Near Me, they are not just seeking proximity—they are looking for reliable consultation, fast delivery, and on-site service support. Indian manufacturers recognize this and maintain regional sales offices, service centers, and technical personnel to provide rapid response.

Customization remains a key differentiator. From CAD-aided design to pump skid fabrication and testing under simulated working conditions, local manufacturers are providing complete, turnkey pump solutions. This ensures that each client receives a pump that is finely tuned to their operational environment and technical requirements.

Whether it’s retrofitting an old plant or integrating pumps into a new automated system, proximity to skilled pump engineers allows industries to minimize downtime and maintain high operating standards.

Support and Maintenance: The Backbone of AODD Pump Performance

Aftermarket services offered by AODD Pump Manufacturers play a decisive role in long-term customer satisfaction. These include preventive maintenance contracts, rapid spare part delivery, diaphragm replacement programs, and technical upgrades.

Reputable manufacturers provide mobile servicing units, on-site diagnostics, and remote fault detection capabilities. Training programs for in-house maintenance staff, troubleshooting manuals, and 24/7 technical helplines are part of the standard service package.

Maintaining optimal performance involves regular checks of air valves, diaphragm wear, inlet/outlet integrity, and leak detection sensors. A good after-sales strategy ensures reduced breakdown frequency, lower total cost of ownership, and maximized productivity.

Future-Proofing with Sustainable Pump Design

Looking ahead, Air-Operated Double-Diaphragm Pump Manufacturers are investing in eco-friendly materials, energy-efficient valves, and modular pump designs. These innovations help industries reduce their carbon footprint, conserve energy, and adapt to stricter environmental regulations.

Sustainability is becoming a competitive advantage. By optimizing air consumption and incorporating recyclable components, manufacturers are setting new benchmarks in green engineering. Integration of digital monitoring tools also promotes predictive maintenance and process automation, paving the way for smart manufacturing ecosystems.

As environmental consciousness grows, industries are aligning with suppliers who not only deliver performance but also reflect a commitment to global sustainability goals.

Conclusion

With a sharp focus on innovation, reliability, and affordability, Indian AODD Pump Manufacturers are shaping the future of industrial fluid handling. Whether you need a standard-duty unit for routine operations or a heavy-duty solution for complex applications, turning to an experienced Air Operated Double-Diaphragm Pump Supplier from India ensures peace of mind. Their global export presence, engineering expertise, and evolving digital platforms allow clients across continents to access quality solutions quickly and efficiently.