Seawater Desalination System Manufacturer in India

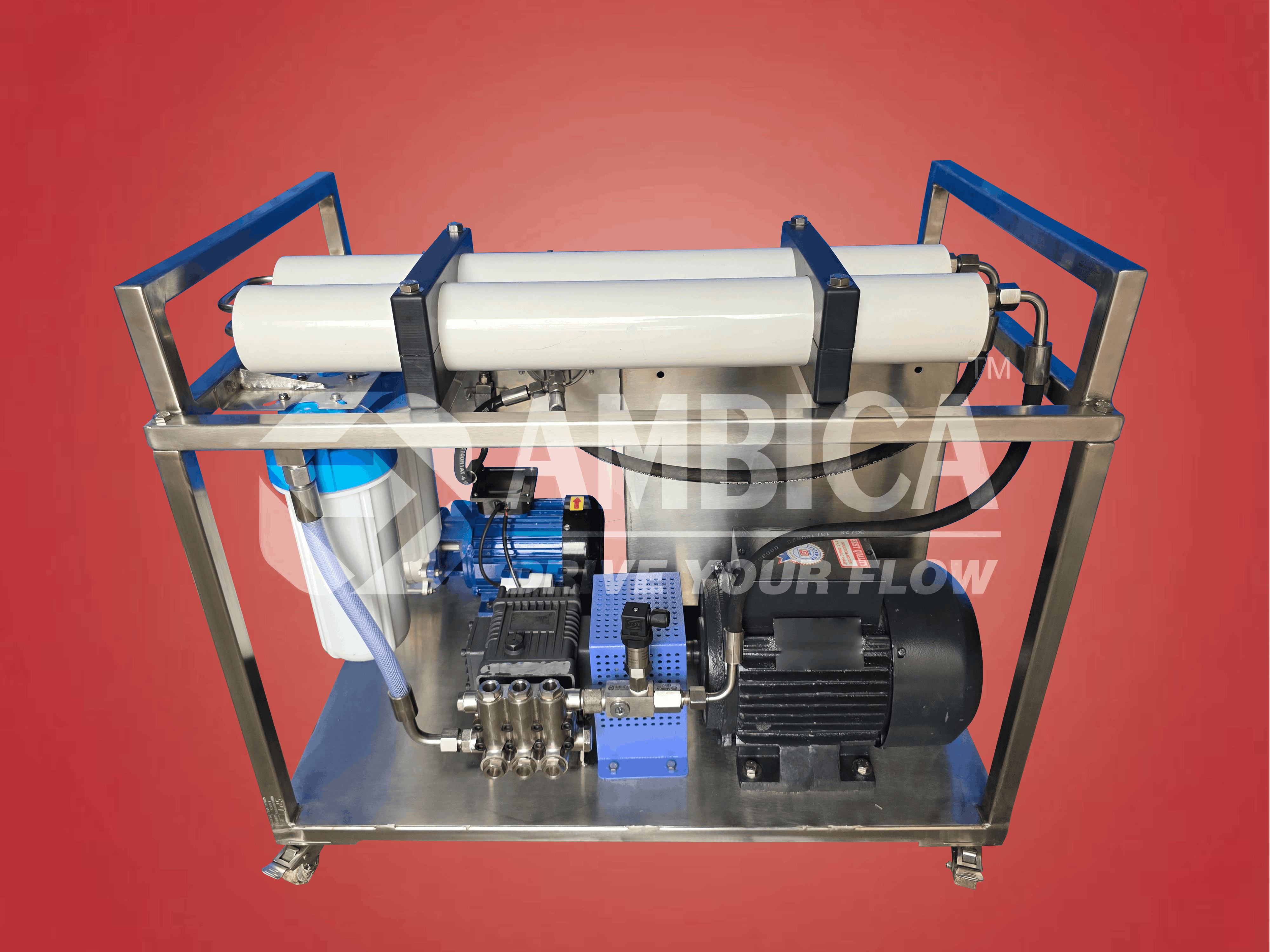

Portable Seawater Desalination System

We are a specialised seawater desalination systems manufacturer and portable desalination plants manufacturer. With our core focused on the research, development, production, and supply of high-performance desalination equipment.

We manufacture seawater desalination plants and portable seawater desalination systems using the best technology and marine-grade materials. Our systems are designed to convert high-salinity seawater into safe drinking water while ensuring stable performance, long service life, and reliable operation in demanding environments.

With 20+ years of successful industry experience, our desalination systems are trusted for coastal, island, marine, and arid-region applications where freshwater availability is limited, and system durability is critical.

Request A Quote

Technical Features of Our Portable Seawater Desalination System

Operational Efficiency & Control

- One-Key Operation: Automated start-up for easy and convenient use.

- Monitoring: Equipped with various flow and pressure testing instruments to monitor operating states in real-time.

- Maintenance: Automatic and regular washing cycles to improve water quality and extend membrane life.

- Ease of Use: Features a simple connection system that is safe and reliable.

Advanced Filtration & Performance

- RO Membrane: Utilises high-quality, famous-brand seawater RO membranes with a salt removal rate of up to 99.7%.

- Pre-Filtration: High-quality cartridge-type pre-filters remove large impurities and algae, with optional manual or automatic control.

- Protection: Cartridge filters are designed to protect and prolong the service life of the RO membrane.

Build Quality & Durability

- Frame & Portability: Fully polished stainless steel 316L frame mounted on a stainless steel 316 trolley wheel system.

- Pumps: Features high-quality SS316L raw water and high-pressure pumps.

- Valves: Includes an SS316L electric slow-open valve to manage high-pressure transitions.

- Fittings: All high-pressure fittings are SS316 for corrosion resistance; low-pressure fittings use food-grade UPVC material.

- Voltage Protection: Integrated high and low voltage protection to prevent system breakdowns.

- Emergency Controls: High-pressure auto cut-off system with an emergency stop button.

Applications of Seawater Desalination Systems

Seaside Locations

Ideal for seaside villas, coastal residences, and beachfront developments.

Island Use

Suitable for island families, resorts, restaurants, hotels, inflatable water islands, and dedicated island drinking water purification systems.

Challenging Water Sources

Effective for salty and alkaline lakes and rivers, especially in Middle Eastern regions.

Arid & Desert Environments

Designed for underground saline water extraction and purification in desert areas.

Marine & Military Use

Suitable for marine boats, ships, army vessels, and lightboats, serving as a dedicated marine drinking water maker.

Our Valuable Clients

Countries We Serve

Why Choose Us

20+ Years of Experience

With over two decades of experience, we manufacture reliable seawater desalination systems designed for long-term operation in marine and high-salinity environments.

Advanced RO Technology

Our systems use high-quality seawater RO membranes with excellent salt rejection and consistent water output.

10,000+ Happy Clients

Industries, marine operators, and institutions trust our desalination systems for dependable freshwater production.

CE & ISO Certified

All systems are manufactured following international quality and safety standards.

Strict Quality Control at Every Stage

Each desalination system undergoes thorough inspection and testing before dispatch.

Trusted for Marine & Harsh Environments

Our systems are widely used in coastal, island, marine, and desert conditions where reliability is essential.

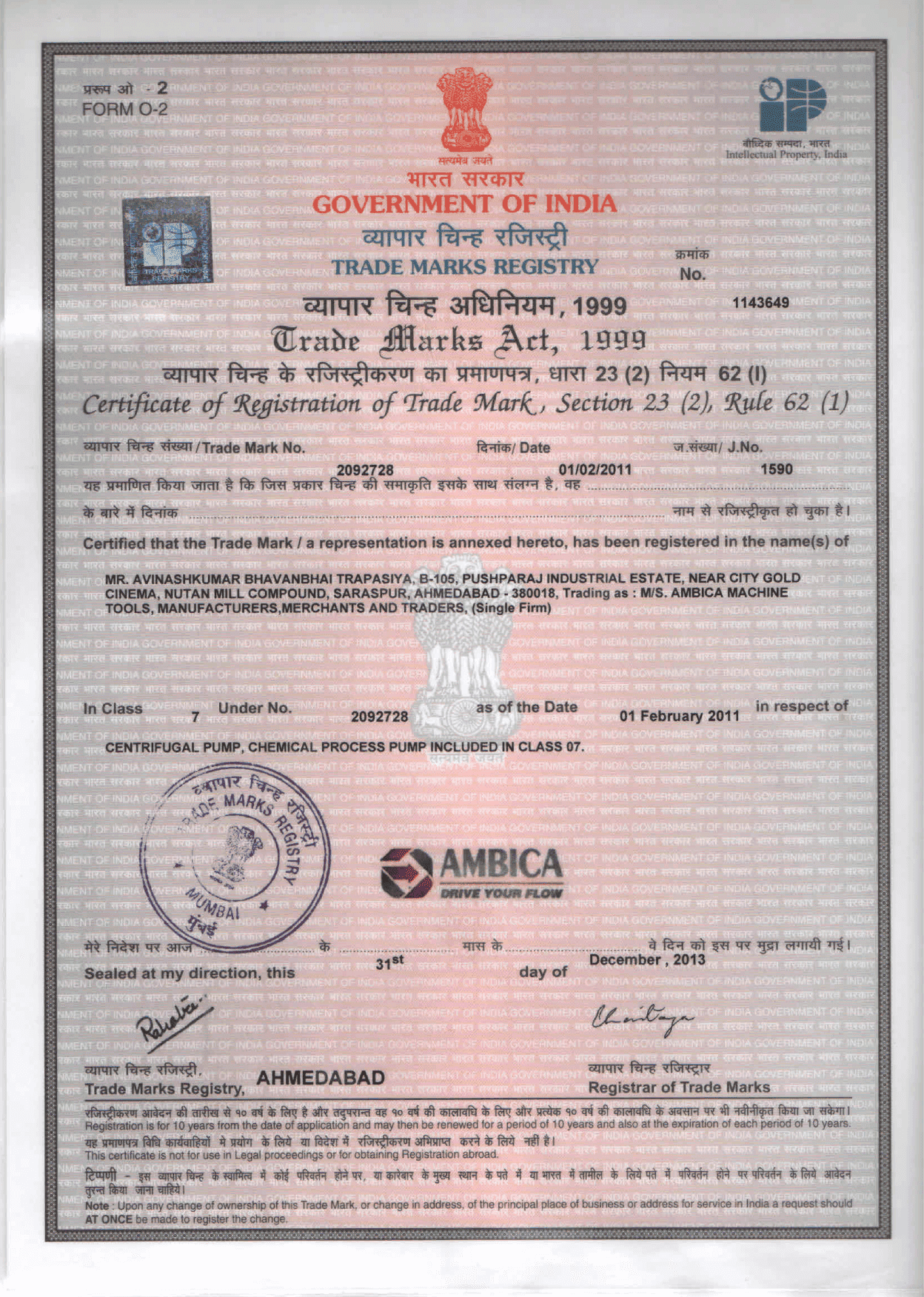

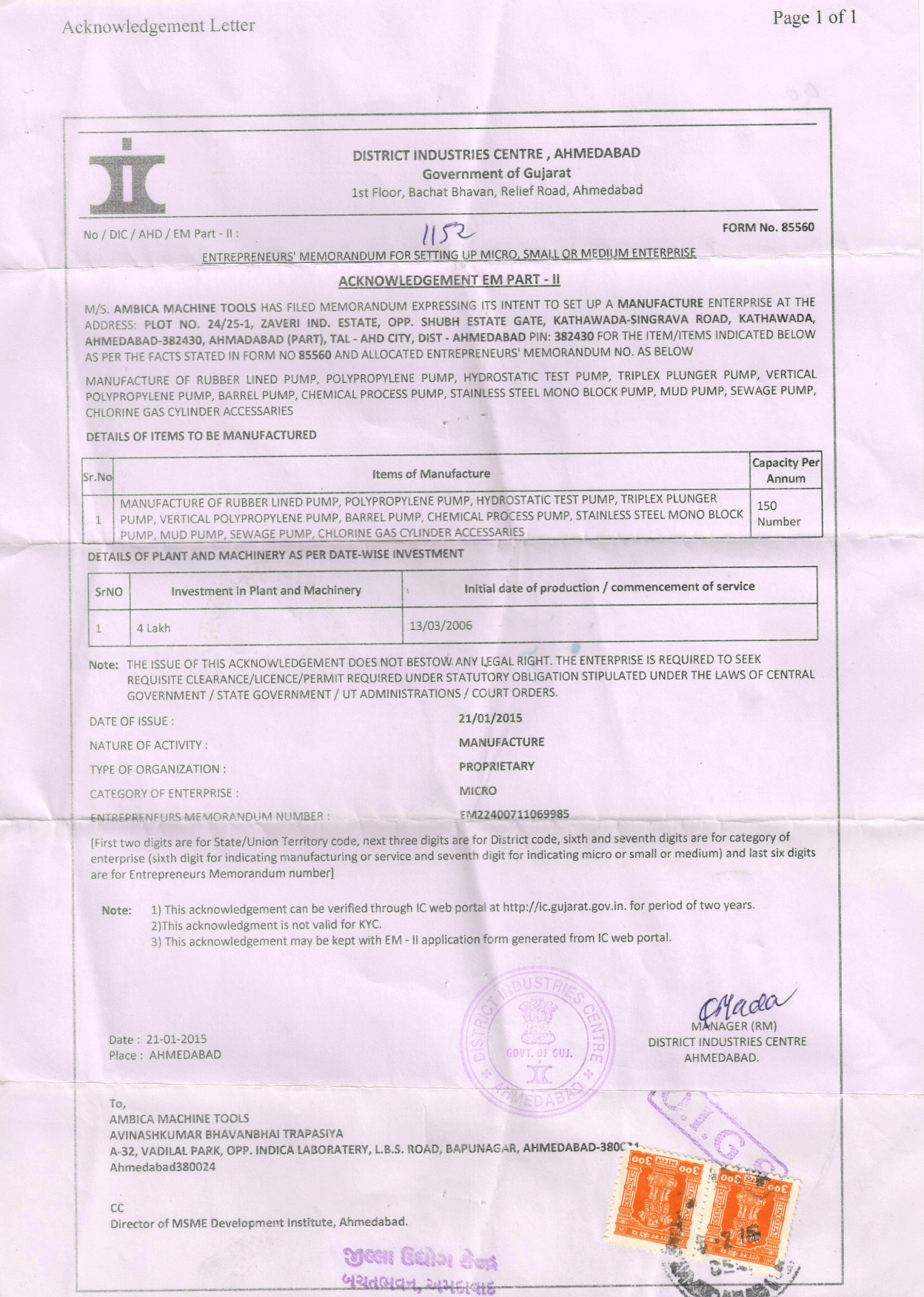

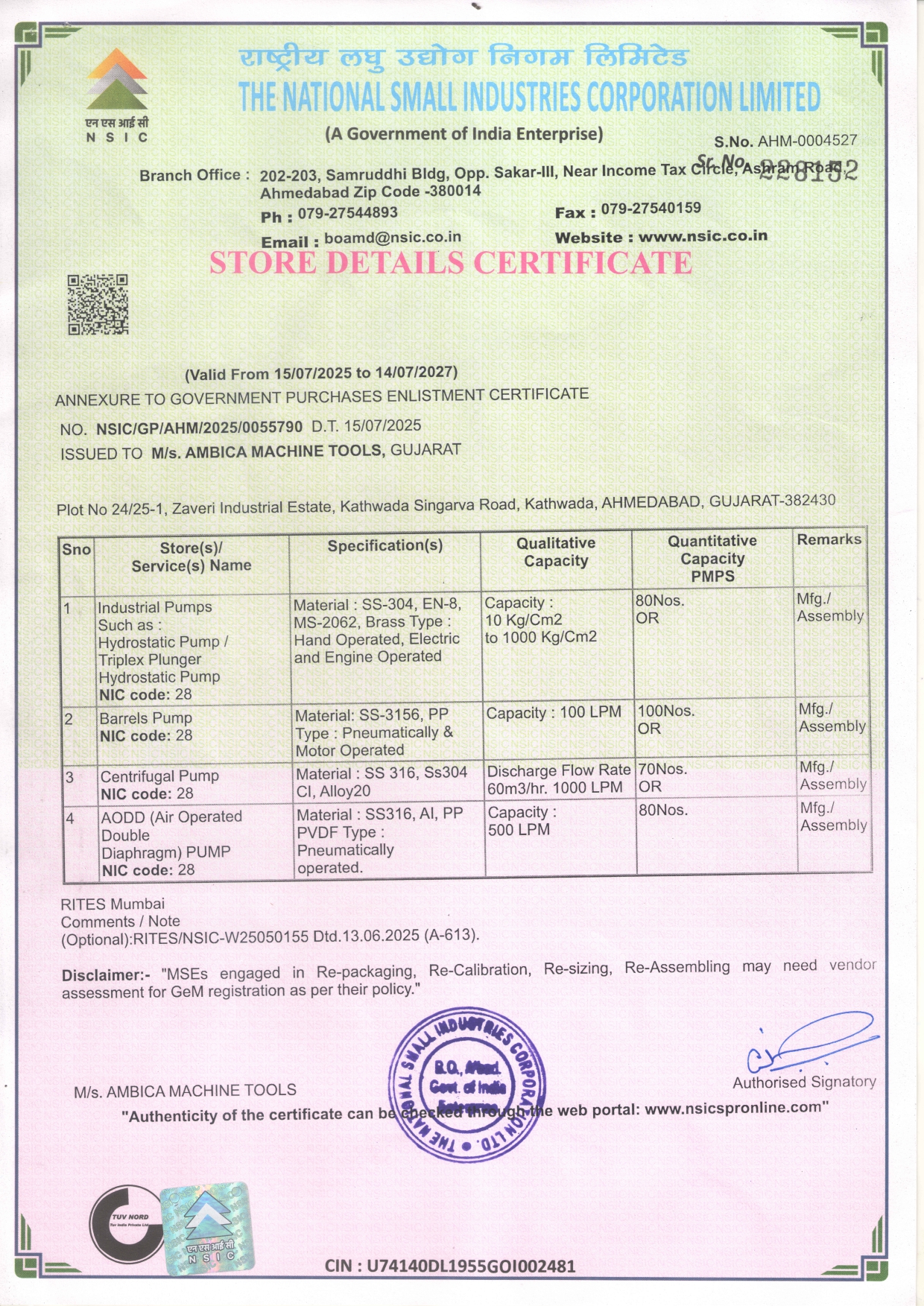

Quality Assurance and Certifications

Industries We Serve

Chemical

- Acid

- Caustic

- Solvent

- Paint

- Shear Sensitive

- Material

Automobile

- Oil

- Solvent

- Paint

- Waste Wate

Food & Medicine

- Liquid Material

- Additive

- Condiment

- Powder

Machinery

- Oil

- Cutting fluid

- Quenching Oil

- Acetone

- Electroplate

- Liquid

- Liquid Waste

Paper Making

- Pulping

- Additive

- Liquid Waste

What our Clients Say

We installed their portable seawater desalination system for coastal use, and the performance has been consistent. The build quality is excellent and suitable for marine conditions.

Industrial Pump and Valve by Ambica Machine Tools is a trusted seawater desalination plant manufacturer. Their desalination plant works reliably on our vessel and provides a stable drinking water output.

We selected their portable desalination plant for island use. The system handles high salinity well and delivers dependable freshwater.

Frequently Asked Questions (FAQs)