2 Way, 3 Way, and 5 Way Manifold Valve Manufacturer & Supplier In India

We are the best ISO-certified 2 way, 3 way, and 5 way manifold valves manufacturer and supplier in India and worldwide for high-pressure instrumentation and process systems. These valves are designed to isolate, vent, and equalise pressure safely during operation, calibration, and maintenance activities.

Valve manifold assemblies are commonly installed with pressure gauges, transmitters, and measuring instruments where accurate pressure control, compact installation, and reliable sealing are required. The block-type design minimises leakage points and improves system safety in demanding high-pressure environments.

Contact UsKey Features of Our Manifold Valves

- Available in 2 way, 3 way, and 5 way configurations for isolation, venting, and pressure equalisation needs.

- Compact block design reduces leakage points and helps improve system safety.

- Suitable for high-pressure instrumentation systems where stable pressure control is required.

- Enables safe isolation and venting during maintenance without disturbing the main line.

- Manufactured in stainless steel and carbon steel to suit different pressures and operating conditions.

Why Choose Our Manifold Valves?

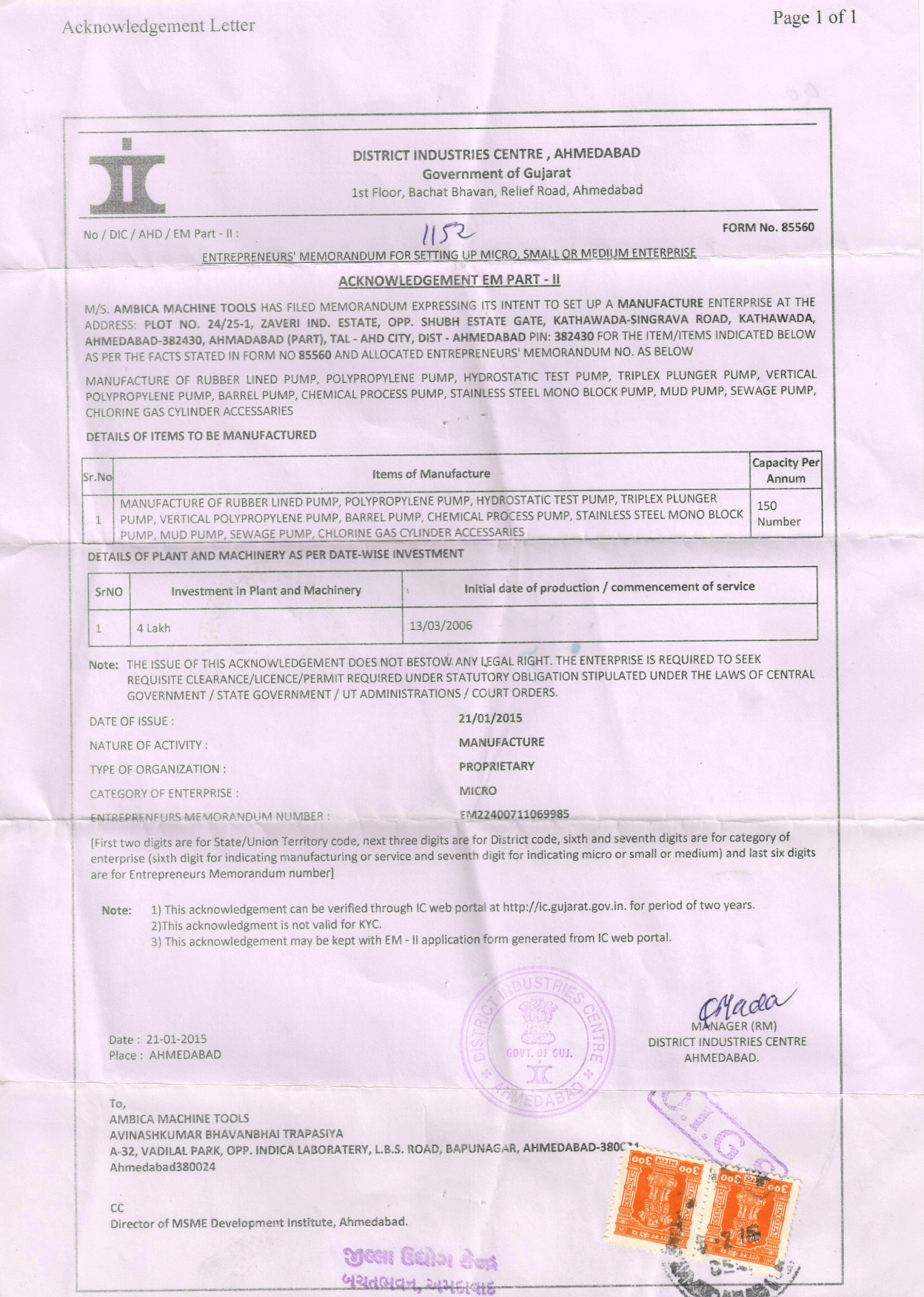

20+ Years of Experience

With more than two decades of experience, we have been supplying manifold valves for instrumentation and high-pressure systems where safe pressure control is critical.

Multiple Product Range

We offer 2 way, 3 way, and 5 way valve manifold options designed to meet different isolation, venting, and pressure equalisation requirements.

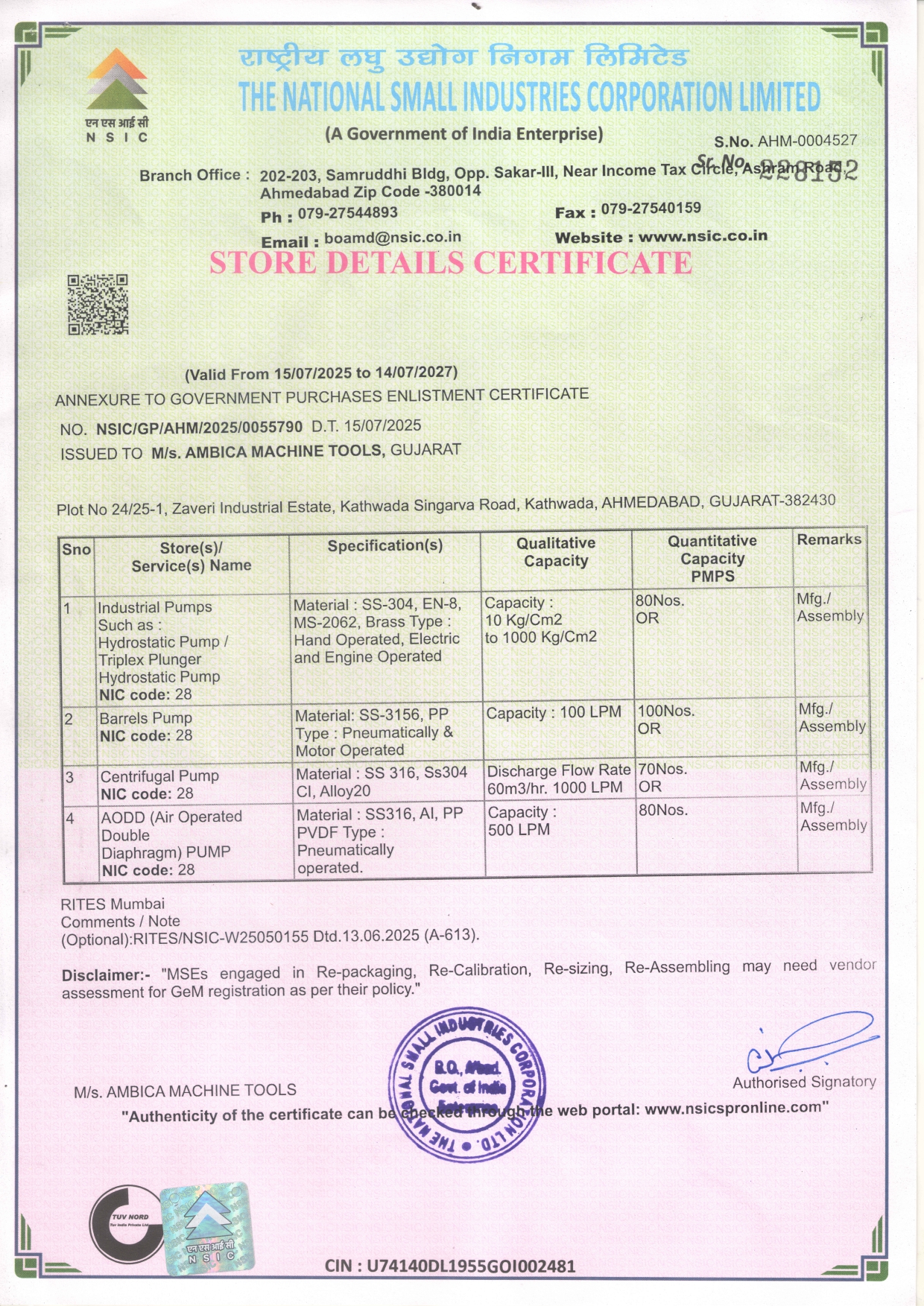

Trusted by Industrial Clients Worldwide

Our manifold valves are supplied to industrial clients across India and international markets, supporting high-pressure instrumentation systems in oil & gas, chemical processing, power, and industrial applications.

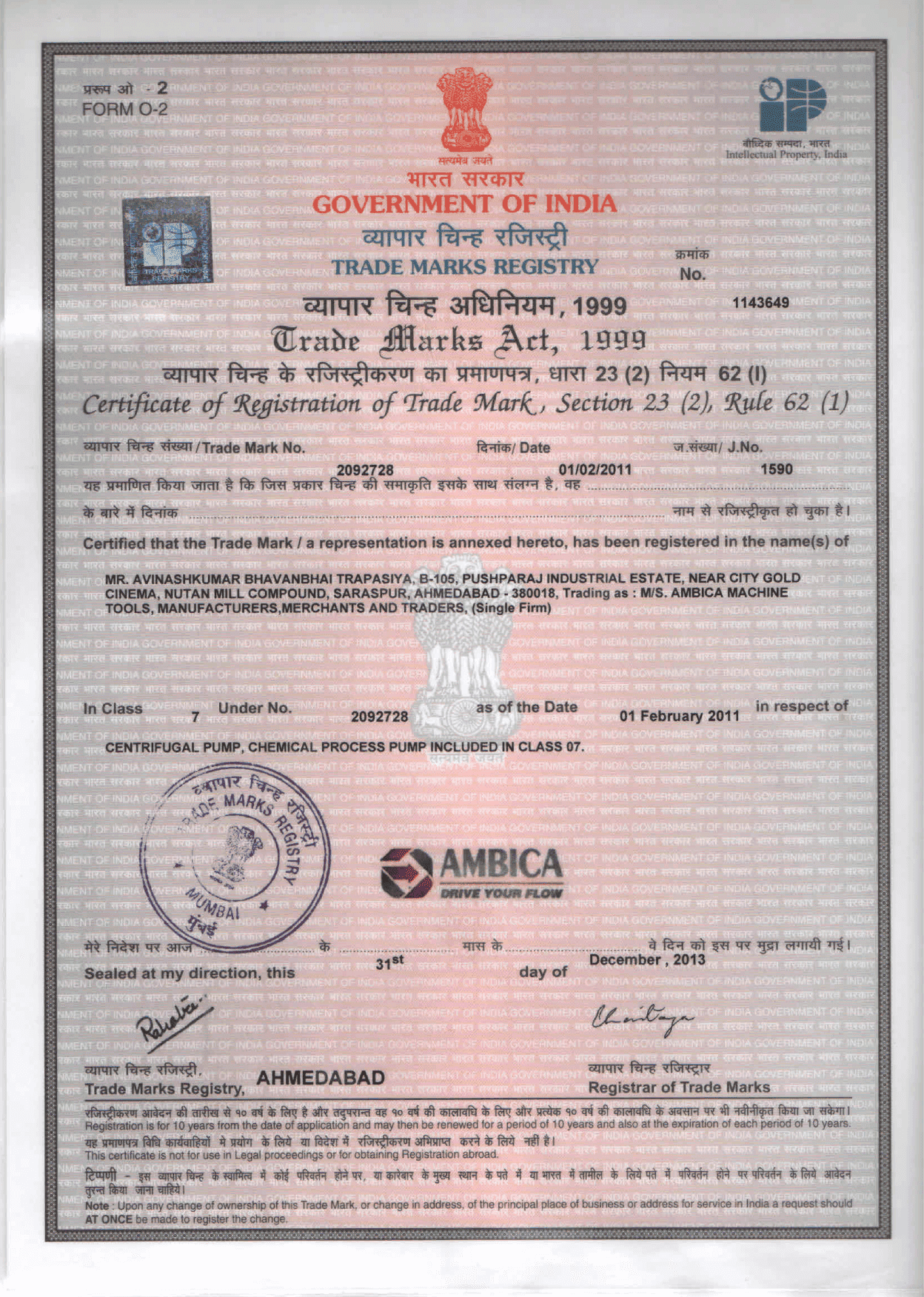

CE & ISO Certified

All our manifold valves are manufactured under ISO-certified processes to meet standard industrial quality and safety requirements.

Superior Quality & QC Practised at All Levels

Each valve manifold is checked for material quality, sealing performance, and smooth operation before dispatch.

Used in Critical Applications

Our manifold valves are used in systems where controlled pressure handling and safe isolation are essential to protect instruments and equipment.

Applications of Our Manifold Valves

Manifold valves are used in high-pressure instrumentation systems where controlled pressure handling is required. They help isolate instruments, allow safe venting of pressure, and support calibration and maintenance activities without affecting the main process line. These valves are commonly installed in compact piping, control panels, and industrial process systems to ensure safe and stable operation.

Pressure Gauge and Transmitter Mounting

Used to isolate pressure gauges and transmitters during calibration, testing, or replacement, allowing safe venting of trapped pressure without shutting down the main process line.

Instrumentation and Control Panels

Installed in instrumentation panels and skids where compact design and reliable pressure control are required for accurate monitoring and operation.

Oil & Gas and Chemical Processing

Used in high-pressure oil, gas, and chemical systems to safely isolate instruments, control pressure flow, and manage venting during maintenance activities.

Power Plants and Process Industries

Applied in power generation and industrial process systems where controlled pressure handling is necessary to protect instruments and maintain system safety.

Pressure Instrument Isolation

Used to isolate pressure gauges and transmitters during testing, calibration, or replacement.

Control Panels and Process Systems

Installed in instrumentation panels and industrial process lines where compact pressure control and safe operation are required.

Our Valuable Clients

Countries We Serve

Quality and Manufacturing Standards

Our manifold valves are manufactured using verified raw materials and controlled machining processes to meet industrial operating requirements. Each manifold valve undergoes dimensional checks, sealing verification, and functional inspection before dispatch to ensure safe and reliable operation in high-pressure instrumentation and process systems.

Quality Assurance and Certifications

Industries We Serve

Chemical

- Acid

- Caustic

- Solvent

- Paint

- Shear Sensitive

- Material

Automobile

- Oil

- Solvent

- Paint

- Waste Wate

Food & Medicine

- Liquid Material

- Additive

- Condiment

- Powder

Machinery

- Oil

- Cutting fluid

- Quenching Oil

- Acetone

- Electroplate

- Liquid

- Liquid Waste

Paper Making

- Pulping

- Additive

- Liquid Waste

What our Clients Say

We installed 3 way manifold valves in our instrumentation panel. The valves performed well during calibration and maintenance work.

The manifold valves were used in our high-pressure testing setup. Installation was straightforward, and pressure control remained stable.

We sourced 5 way manifold valves for our chemical process line. The build quality was good, and the operation has been reliable.

Frequently Asked Questions (FAQs)