Bleed Valve Manufacturer & Supplier in India & Globally

Bleed valves play an important role in high-pressure instrumentation systems. They are used to release signal line pressure to the atmosphere before removing a gauge or during calibration of control devices. Releasing trapped pressure before maintenance helps protect technicians and connected equipment. As the trusted ISO-certified bleed valve manufacturer & supplier in India and worldwide, we manufacture strong and dependable bleed valves for high-pressure installations. Our high pressure bleed valves are designed to handle demanding industrial conditions while allowing smooth and controlled venting of trapped fluid or gas.

Contact UsKey Features of Our Bleed Valve

- Designed for safe use in high-pressure piping and instrumentation systems, allowing controlled release of trapped fluid or gas before maintenance or calibration.

- Manufactured from SS 316, SS 316L, SS 304, and Carbon Steel to provide high strength and corrosion resistance for chemical, hydraulic, and water applications.

- Features a blow-out proof stem with a back-stop safety design to prevent accidental stem ejection and improve operator safety during venting.

- Fitted with ViltonTM or TeflonTM packing to provide a tight, leak-free seal, ensuring controlled venting and long service life under repeated use.

- Compact and lightweight construction allows easy installation in confined spaces such as instrument panels, manifolds, and control skids without compromising performance.

Why Choose Our Bleed Valve?

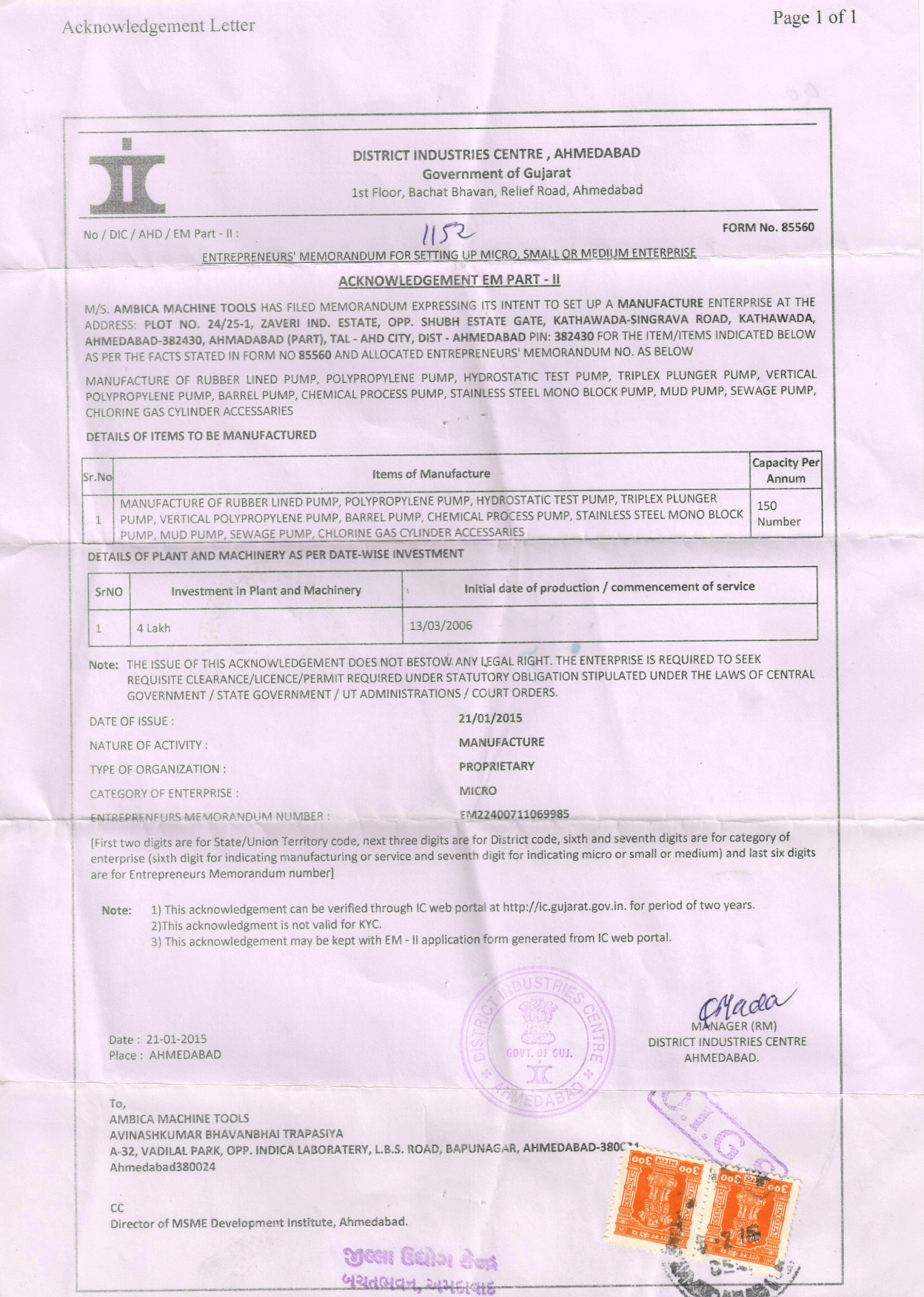

20+ Years of Experience

Our decades of manufacturing expertise ensure that every bleed valve we produce meets the exact tolerances required for high-risk industrial venting applications.

Multiple Product Range

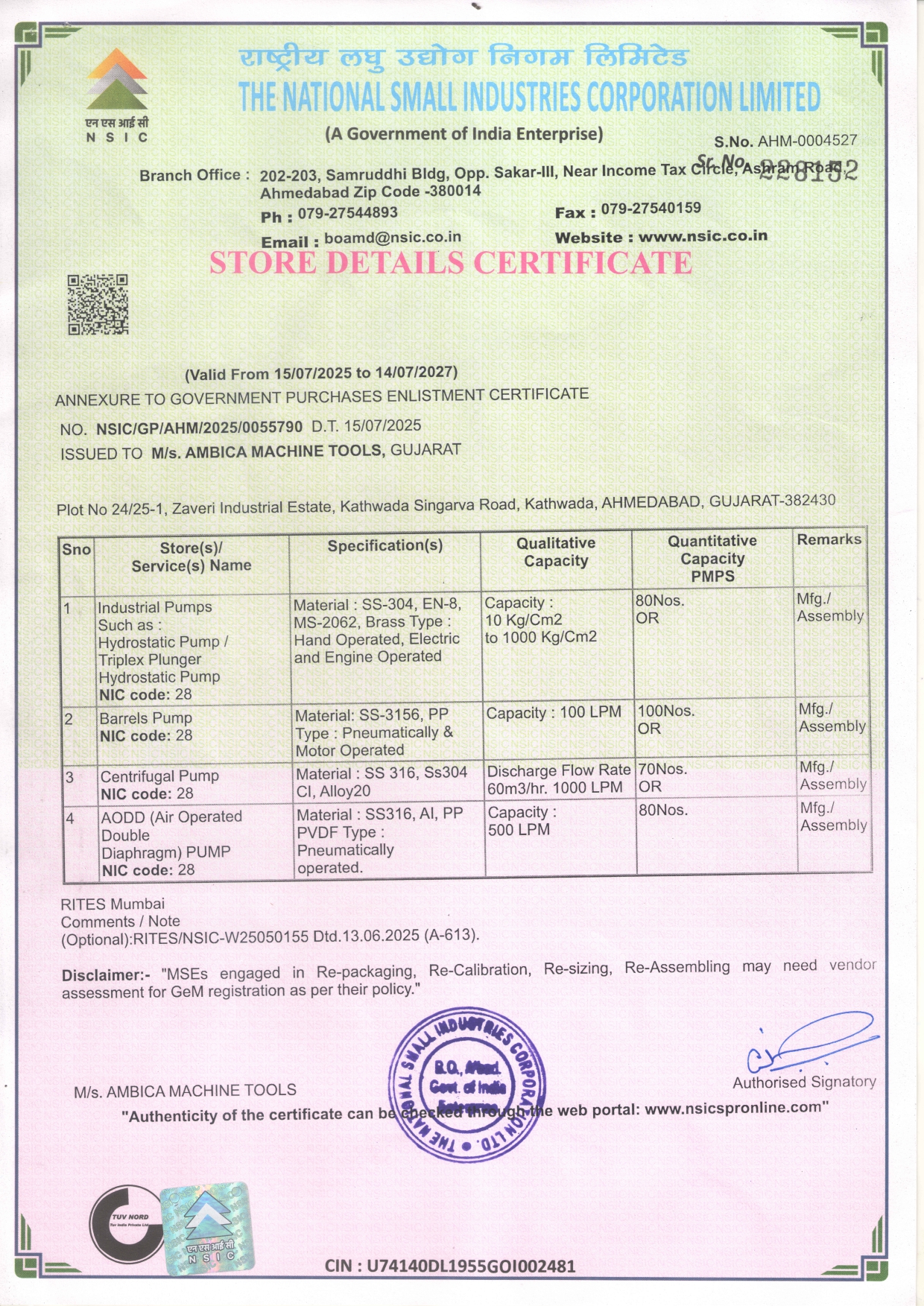

We offer a range of bleed valves in different sizes, end connections, materials, and pressure ratings to suit various high-pressure instrumentation and piping applications.

Trusted by Industrial Clients Worldwide

Our commitment to quality has built a global network of satisfied partners who rely on our valves for their most critical pressure systems.

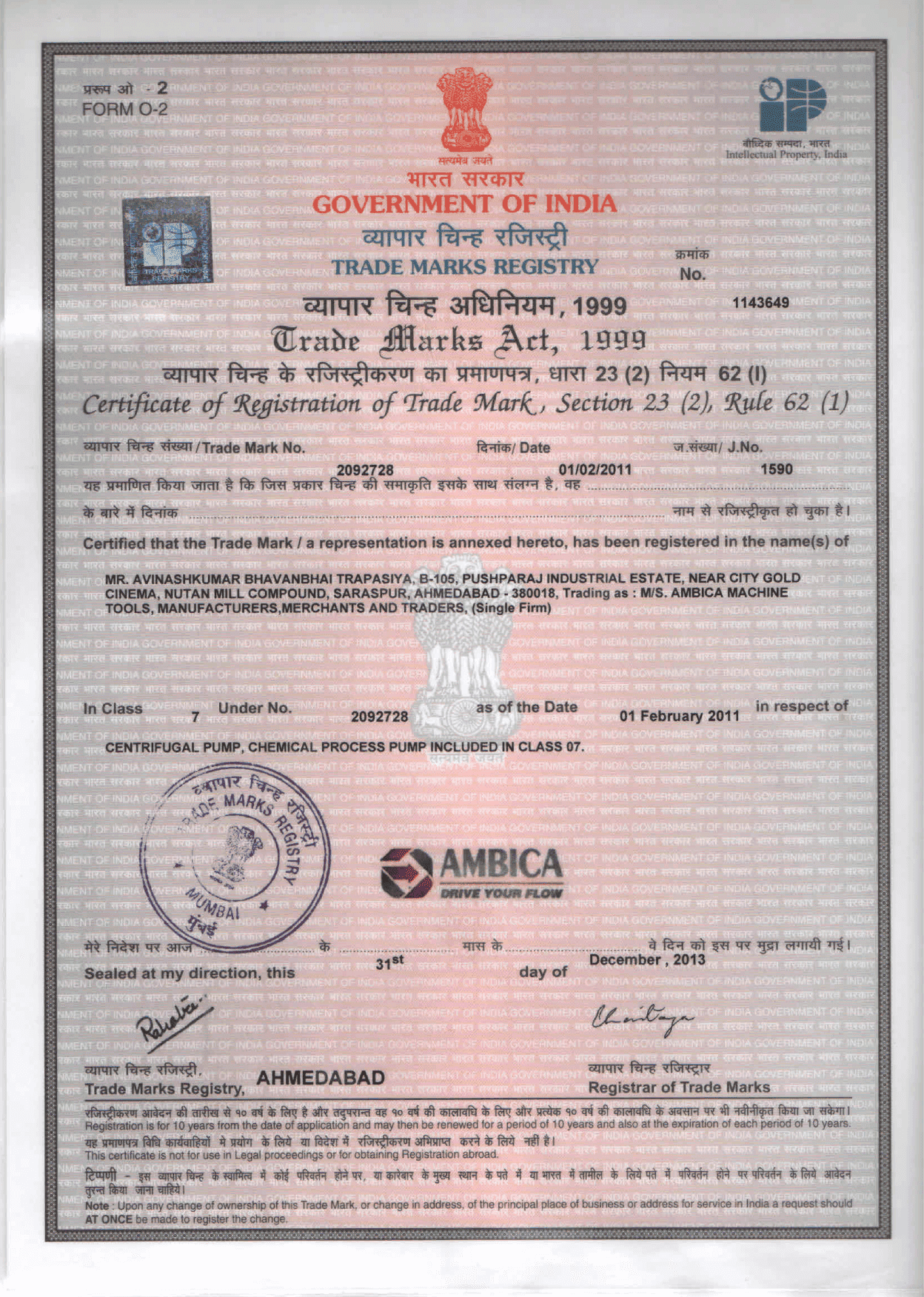

CE & ISO Certified

We follow ISO quality systems and CE safety standards during manufacturing to make sure our products meet international requirements and are safe to use in regulated industrial environments.

Superior Quality & QC Practised at All Levels

Each bleed valve undergoes meticulous pressure testing and material verification to ensure it performs flawlessly at its maximum rated 700 bar pressure.

Used in Critical Applications

Our bleed valves are widely used in critical pressure systems such as oil & gas, chemical processing, and hydraulic units where safe and controlled pressure release is essential.

Applications of Our Bleed Valve

A bleed valve is mainly installed on instrument manifolds and gauge valves to release pressure before removing instruments. This helps technicians work safely during maintenance and calibration. They are also commonly used in hydraulic systems, chemical processing lines, and high-pressure pipelines to release trapped pressure during maintenance, testing, or calibration operations.

Instrument Manifolds

Installed in manifold blocks to release pressure before gauge calibration or instrument removal. This helps protect technicians and prevents damage to sensitive measuring instruments.

Hydraulic Panels

Used in high-pressure hydraulic control panels to release trapped fluid or air during maintenance, troubleshooting, or system shutdown.

Gas Distribution

Releases pressure from gas lines during servicing or equipment replacement, helping reduce the risk of sudden or uncontrolled gas discharge.

Refineries

Installed on pressure instruments monitoring hydrocarbon process lines to allow controlled pressure venting in volatile and high-temperature environments.

Pneumatic Systems

Releases trapped compressed air from pneumatic circuits to prevent sudden actuator movement during maintenance activities.

Chemical Processing

Provides a controlled outlet for venting process fluids in chemical plants and pilot systems, supporting safer handling of corrosive or reactive media.

Our Valuable Clients

Countries We Serve

Quality and Manufacturing Standards

Our bleed valves are manufactured using verified raw materials and precision machining processes to meet demanding industrial requirements. Each bleed valve undergoes dimensional inspection, pressure testing, and sealing checks before dispatch to ensure safe, reliable performance in high-pressure instrumentation and piping systems.

Quality Assurance and Certifications

Industries We Serve

Chemical

- Acid

- Caustic

- Solvent

- Paint

- Shear Sensitive

- Material

Automobile

- Oil

- Solvent

- Paint

- Waste Wate

Food & Medicine

- Liquid Material

- Additive

- Condiment

- Powder

Machinery

- Oil

- Cutting fluid

- Quenching Oil

- Acetone

- Electroplate

- Liquid

- Liquid Waste

Paper Making

- Pulping

- Additive

- Liquid Waste

What Our Clients Say

The bleed valves supplied for our Chennai plant are very durable. The pressure venting is safe and well controlled.

The material quality of the SS 316L bleed valves is excellent. The Teflon packing provides a reliable, leak-free seal.

The compact design makes these bleed valves easy to operate. They have improved safety during maintenance work at our refinery.

We bought a bleed valve from Industrial Pump and Valve by Ambica Machine Tool for our refinery project. The build quality is solid, installation was simple, and pressure release is smooth and controlled. Very reliable product for high-pressure applications.

Frequently Asked Questions (FAQs)