Syphon Manufacturer & Supplier in India

Reliable industrial syphons are important for protecting pressure gauges, transmitters, and switches from high-temperature media like steam. Industrial Pump and Valve is a leading ISO-certified syphon manufacturer in India & worldwide. We design these components with pigtail or coil configurations to safely dissipate heat, preventing damage to sensitive instruments. With 20+ years of industry experience, our syphons are built to meet strict pressure ratings, ensuring dependable performance and long-term reliability in thermal processing and fluid systems globally.

Contact UsKey Features of Our Syphon

- Protects pressure gauges, transmitters, and switches from high-temperature media like steam, ensuring safe and accurate readings.

- Manufactured in SS 304, SS 316, and Carbon Steel for corrosion resistance and long-lasting performance in industrial environments.

- Designed with pigtail or coil shapes to dissipate heat effectively and prevent internal damage to instruments.

- Available in 1/4″ to 1/2″ sizes with NPT and BSP threaded connections for easy integration into standard piping systems.

- Tested for pressure integrity up to SCH 120 to withstand high-pressure conditions without deformation.

Why Choose Our Syphon?

20+ Years of Experience

With over two decades of expertise in manufacturing industrial Syphons, we have perfected our pipe-bending, threading, and machining processes to ensure precise dimensions, smooth finishes, and safe performance in high-temperature applications.

Multiple Product Range

In addition to Syphons, our portfolio includes a wide range of valves and fittings. This allows clients to source complete pressure-measurement protection assemblies from a single, trusted manufacturer.

Trusted by Worldwide Clients

Our Syphons are supplied to power plants, oil & gas refineries, chemical industries, and process plants worldwide. We are known for consistent quality, timely delivery, and dependable product performance.

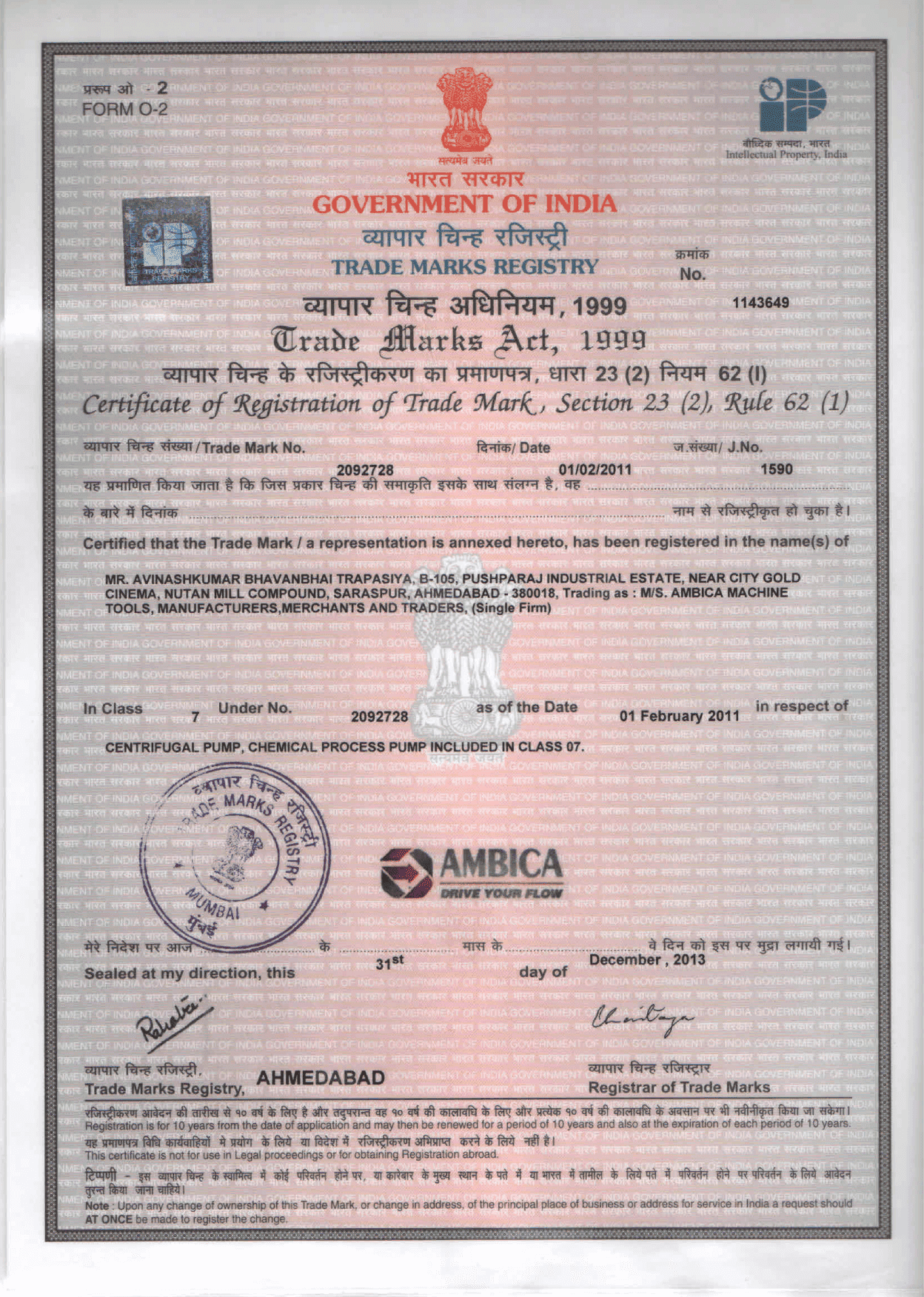

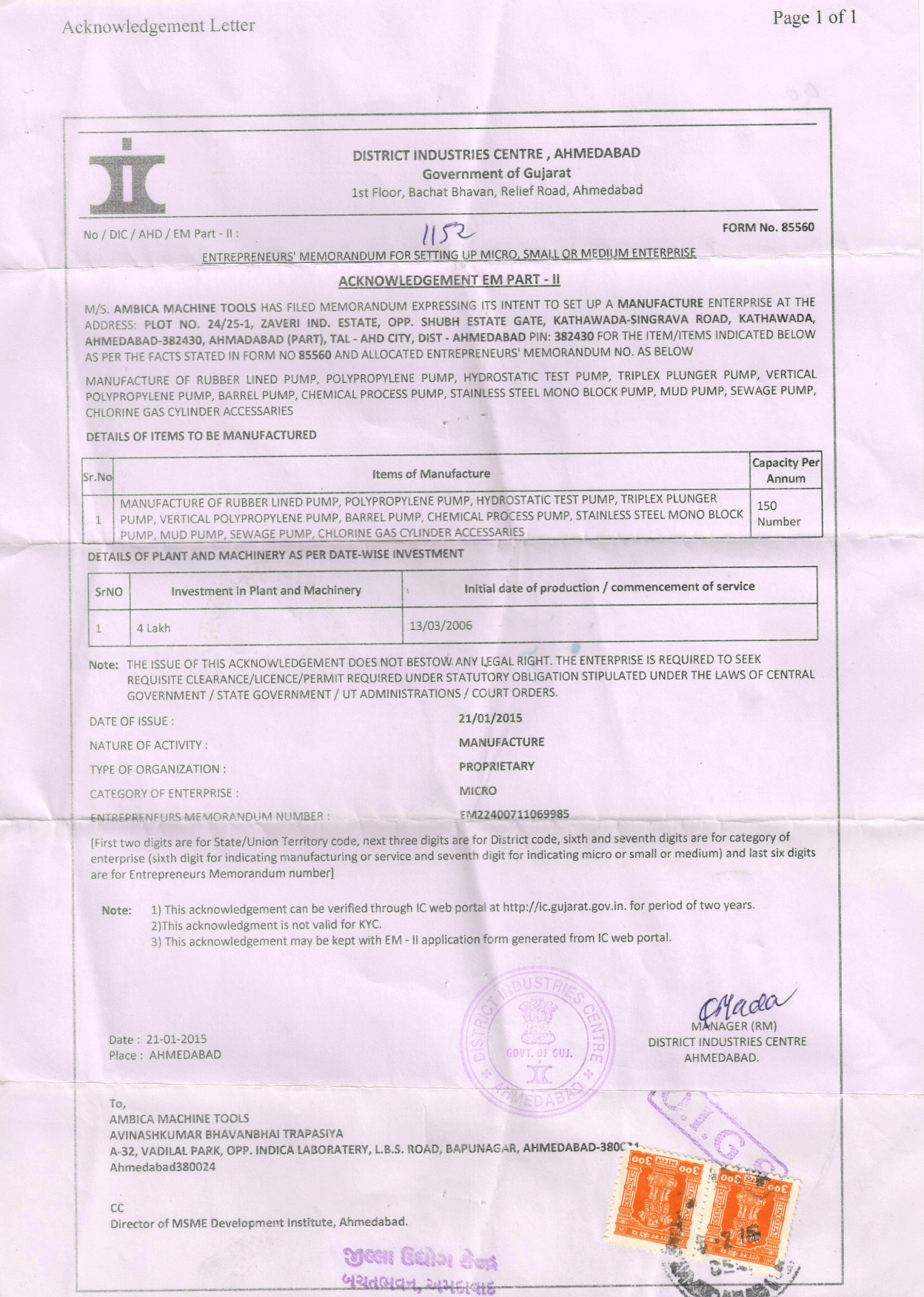

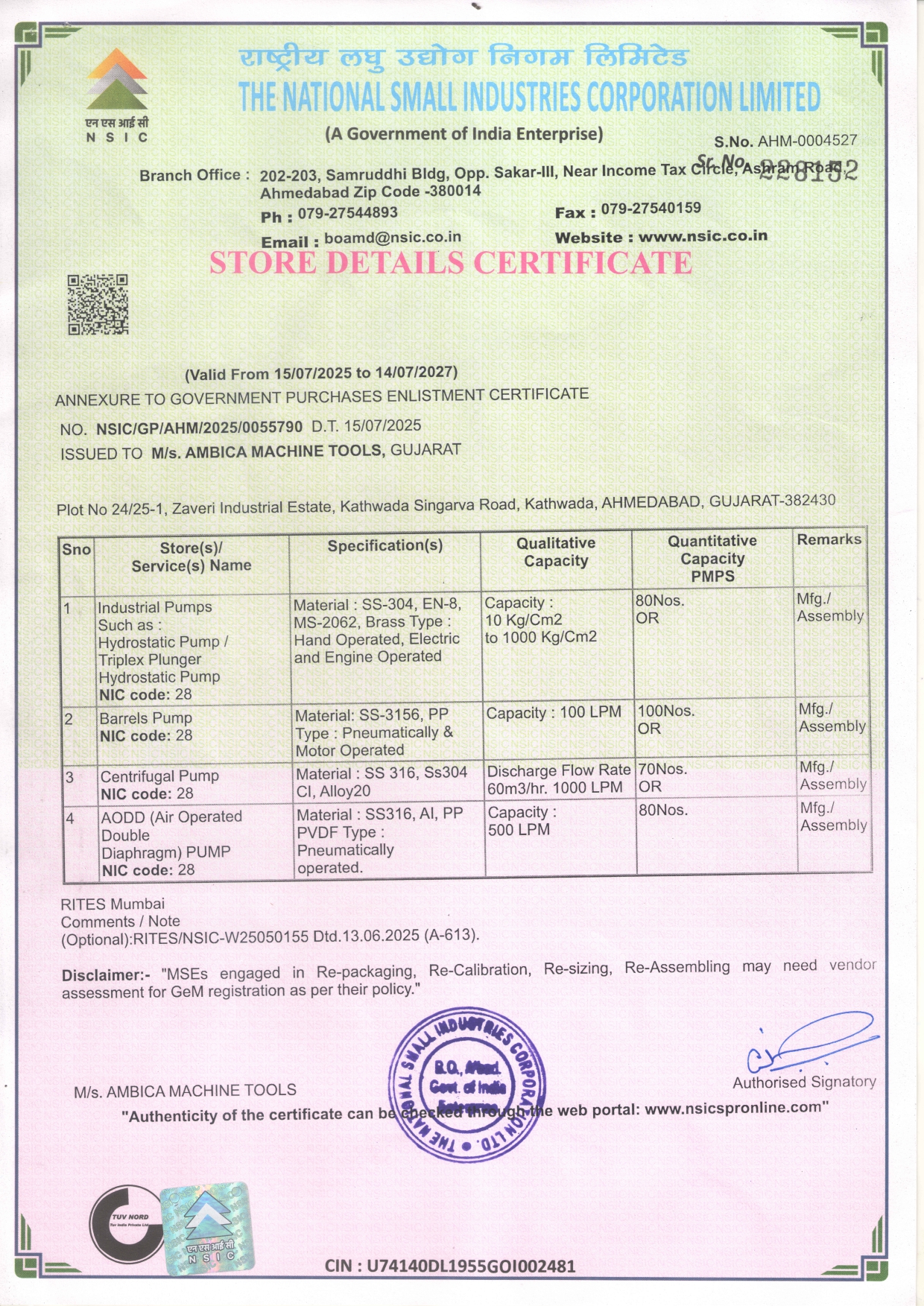

CE & ISO Certified

Our manufacturing facility follows strict international quality standards. Every syphon is produced under controlled processes, ensuring traceability, compliance, and reliability for global industrial applications.

Superior Quality & QC Practised at All Levels

Each syphon undergoes stringent quality inspections and pressure testing to verify leak-proof construction and structural integrity. We carefully examine raw materials, bending accuracy, and threaded connections to ensure flawless performance.

Used in Critical Applications

Our industrial Syphons are specifically designed to protect pressure gauges, transmitters, and switches from high-temperature steam and hot fluids. They create a thermal barrier that ensures safe, accurate, and long-lasting instrument operation in demanding environments.

Applications of Our Syphon

Syphons are important whenever pressure instruments are installed on high-temperature lines. They are primarily used to condense steam and protect gauges from hot vapours in various industrial sectors.

Steam Boilers

Installed on boiler steam lines to protect pressure gauges from direct contact with hot steam, ensuring safe and accurate readings.

Chemical Processing

Used in pipelines carrying hot or corrosive fluids to prevent instrument damage and maintain reliable measurements.

Oil & Gas Refineries

Fitted on high-pressure piping to safeguard gauges and transmitters, ensuring safe and stable operation.

Power Generation

Applied to turbine and auxiliary lines to stabilise pressure readings and protect sensitive sensors from heat.

HVAC Systems

Used in hot water and steam lines to shield pressure instruments and maintain accurate monitoring in large-scale plants.

Food & Beverage

Installed on steam-jacketed vessels and pipelines to prevent gauge damage and ensure precise pressure control.

Our Valuable Clients

Countries We Serve

Quality and Manufacturing Standards

We maintain strict control over the syphon manufacturing process by using certified SCH 40 to SCH 120 seamless pipes. Every component is carefully machined and welded to ensure precise threads and leak-proof performance, even in high-pressure or high-vibration industrial environments.

Quality Assurance and Certifications

Industries We Serve

Chemical

- Acid

- Caustic

- Solvent

- Paint

- Shear Sensitive

- Material

Automobile

- Oil

- Solvent

- Paint

- Waste Wate

Food & Medicine

- Liquid Material

- Additive

- Condiment

- Powder

Machinery

- Oil

- Cutting fluid

- Quenching Oil

- Acetone

- Electroplate

- Liquid

- Liquid Waste

Paper Making

- Pulping

- Additive

- Liquid Waste

What our Clients Say

The SS 316 pigtail syphons were installed on our steam boiler gauges, and the performance has been excellent. They effectively protect the instruments from direct steam exposure and maintain accurate readings.

We bought SCH 80 syphons from Industrial Pump and Valve, a reliable syphon manufacturer in India, for our refinery project. Installation was straightforward, and the units handled high-pressure and high-temperature lines without any issues.

We installed syphons on our chemical processing lines to protect pressure gauges from hot and corrosive media. The performance has been consistent, and they significantly improved monitoring accuracy and instrument lifespan.

The build quality of the SS 304 syphons is excellent. We installed them in our power plant steam lines, and they provide reliable protection for our pressure gauges with no leakage issues.

We required SCH 120 syphons for a high-pressure application, and Industrial Pump and Valve delivered exactly as specified. The threading accuracy and finish quality made installation quick and hassle-free.

Frequently Asked Questions (FAQs)